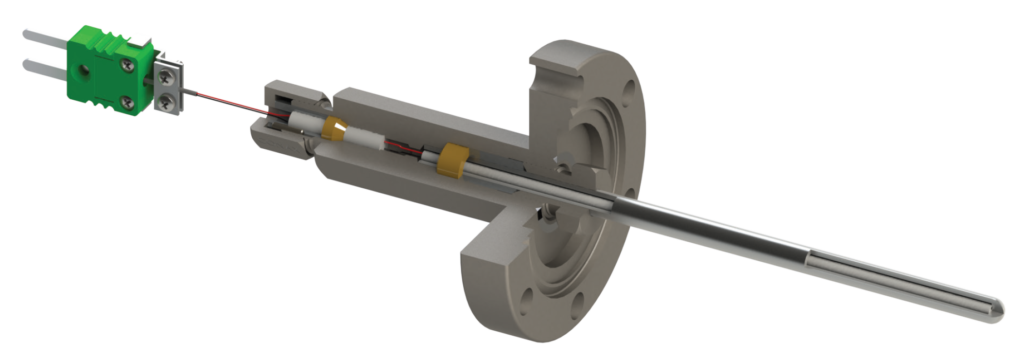

Combo Thermocouple Fitting

Conax Technologies have introduced a thermocouple design that has both a standard compression seal for the thermocouple sheath and a secondary seal for the output wires. The dual seals ensure that if the thermocouple sheath breaks or wears out, there will still be no leak into or out of the process. In-process leaks under vacuum or under pressure can be costly in terms of lost time, materials and finished product. Under certain circumstances, they can also be extremely dangerous, so when customers asked Conax for a solution that would eliminate the risk of in-process leaks caused by sheath failures, they devised the idea for a combo fitting.

For vacuum applications, these dual fittings are ideal for processes that take many days to complete, utilize expensive raw materials, or when it would be especially costly to lose the finished product due to a leak into the process. For example, a solar manufacturer with a 20-day poly-crystalline ingot growth cycle, experienced a leak into the chamber during a cycle, ruining the ingot and costing the customer time and money. The Conax combo fittings eliminate this possibility.

Leaks out of a pressurised chamber can be even more serious for processes containing dangerous chemicals. For example, a Conax customer was running a process to dispose of old chemical weapons during which the bomb would be sealed in a chamber, detonated and the atmospheric temperature inside the chamber raised to destroy the chemical contaminates. The Conax combo fitting ensures that no lethal gas would leak from the chamber during the disposal process, even if damage to the thermocouple occurs.

Conax can customise a combo fitting to your unique requirements using any two of their standard fittings. Talk to us to find out if a Conax combo fitting is right for your process.

D5 Creation

D5 Creation