Laser Linc

LaserLinc provides solutions for in-process and off-line non-contact measurement and visualisation through innovative products and extensive application knowledge. Their gauging and interface products help reduce material usage, enhance production efficiency, minimise scrap, and improve both process and product quality. The micrometres and ultrasonic wall measurement products are designed by LaserLinc employees at their office in Fairborn, Ohio, and are made in the U.S.A. They are tested and certified to meet safety standards in Europe and North America, including CE, UL, and CSA certifications.

Laser Micrometers

LaserLinc understands how critical your in-process and off-line measurements are, for outside diameter, ovality, wall thickness, concentricity, profile and more.

Automated Sample Inspection

LaserLinc’s non-contact measurement solutions are also well suited to off-line sample measurement. Our products ensure accuracy and simplify the quality inspector’s job. You can virtually eliminate operator error through non-contact measurement and automatic checking and recording of results.

Surface Flaw Detection

The FlawSense™ system is a high-speed laser line triangulation measurement and defect detection system that continuously monitors critical material properties in continuously extruded or formed rubber, plastic, wood, shaped metals, wire and cable.

Profile Measurement

The Profile Vu™ system is a high-speed laser line triangulation measurement and defect detection system that continuously monitors critical material properties in continuously extruded or formed rubber, plastic, wood, shaped metals, wire and cable. The system’s 360-degree surface coverage means superior defect detection capabilities when compared to laser micrometres. Defects can be detected in-process and reviewed in 3D.

Profile Visualisation

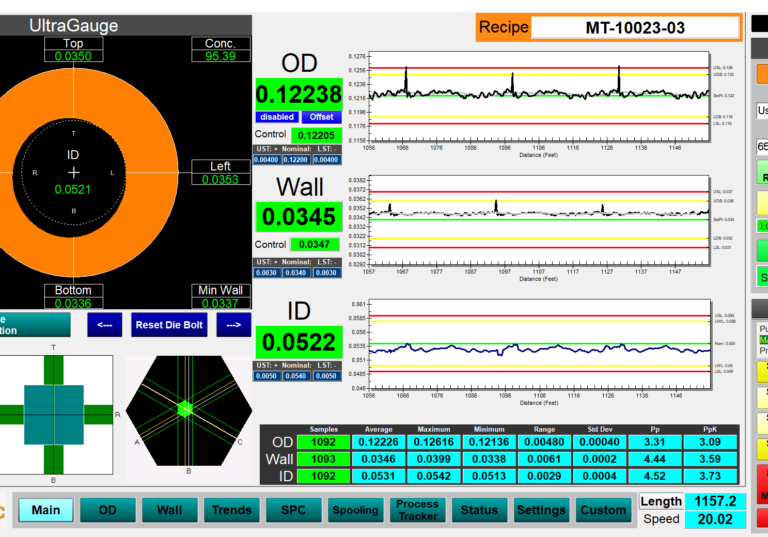

Gauges provide huge amounts of instantaneous data in real-time, so it’s impossible for an operator to assimilate what is happening in the process. That’s why LaserLinc developed a unique open-architecture software solution for process visualisation, allowing its own instruments and those of other vendors to be connected via a variety of gauge interfaces, for process monitoring, display, control and reporting.

Ultrasonic Wall Measurement

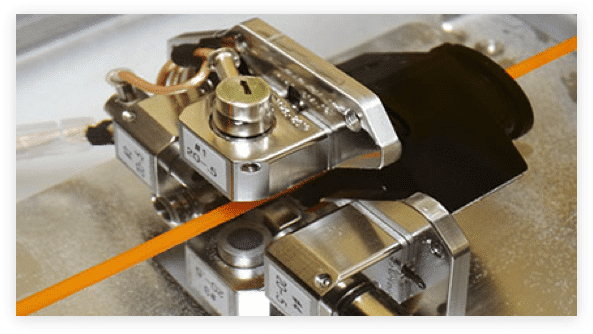

LaserLinc’s ultrasonic devices measure wall thickness or layer thickness of plastic, rubber, glass and metal products like tubing, hose, pipe, insulated wire and cable.

D5 Creation

D5 Creation