Strain Gauges

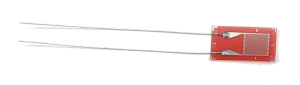

Techni Measure supply a wide range of strain gauges from Japanese manufacturer TML to cover nearly all types of strain measurement applications, and we hold a very large range of gauge types in UK stock for fast delivery.

The majority of strain gauges are supplied in packets of 10 gauges, with each pack including gauge factor and thermal calibration data applicable to the gauge manufacturing lot. The information below describes our range of strain gauge types, including typical applications and selection criteria. For further advice on the selection of gauges for your specific application please contact us.

For information on the application and use of strain gauges, please see our Introduction to Strain Gauging article, or contact us for advice or information on our training services. We also offer a number of our most popular ranges of strain gauges and accessories through our online store.

TML Strain Gauge Part Codes

The part code definition for our range of strain gauges from TML is as follows:

| Gauge Series | Grid Pattern | Active grid length (mm) | Special Functions * | Gauge resistance (ohms) ** | Thermal compensation (ppm/°C) | Integral lead wire length (m) *** | Integral lead wire type *** | ||||

F |

LA |

– |

3 |

T |

– |

350 |

– |

11 |

– |

3 |

LJCT |

* not included for standard gauges

** not included for gauges with standard 120ohm resistance

*** not included for standard gauges with no leadwires

EXAMPLES:

FRA-5-23 – Foil three-element rosette gauge, 5mm active length (120ohm standard resistance), 23ppm/°C thermal compensation (aluminium)

FLA-3T-350-11-3LJCT – Foil single element linear gauge, 3mm active length, including thermocouple, 350ohm resistance, 11ppm/°C thermal compensation (mild steel), with 3m 3-wire parallel 0.11mm² vinyl leadwire

Gauge Series

The selection of gauge series will depend on the specimen material, the temperature and environment in which the testing will be performed and the type of strain measurement that is required. Techni Measure will be happy to advise on the optimum gauge series for your application, please contact us. We hold a large selection of gauges in stock, a small selection of which are also available to purchase online. For details on our full current stocking please contact us for more information

| CODE | Description | Grid Size Range (mm) | TemperatureRange (°C) |

| F | General purpose foil | 0.2 to 10 | -20 to +80 |

| WF | Waterproof foil – with integral leadwires, encased in epoxy | 3 to 6 | 0 to +80 |

| QF | High temperature foil | 0.2 to 6 | -20 to +200 |

| ZF | High temperature foil | 1 to 6 | -20 to +300 |

| EF | High temperature foil, miniature size | 0.2 | -196 to +300 |

| CEF | Wide temperature range | 1 to 6 | -269 to +200 |

| CF | Cryogenic temperature foil | 1 to 6 | -269 to +80 |

| AW | Weldable series for very high temperatures or harsh environments | 4 to 8 | -196 to +800 |

| P | Polyester wire for concrete/mortar with large aggregate size | 60 to 120 | -20 to +80 |

| PF | Polyester foil for concrete/mortar | 10 to 30 | -20 to +80 |

| FLM/WFLM | Metal backed foil for long term concrete/mortar (waterproof version available) | 30 to 60 | -20 to +80 |

| PM | Moulded wire for embedment into concrete/mortar, with integral leadwire | 60 to 120 | -20 to +60 |

| PMF | Moulded foil for embedment into concrete/mortar/asphalt, with integral leadwire | 50 to 60 | -20 to +60 |

| KM | Strain transducer for embedment in concrete/mortar/asphalt/resin for long term use, with integral leadwire | 31 to 200 | -20 to +180 |

| UBF | Foil gauge for use on composite materials | 0.3 to 1 | -30 to +130 |

| BF | Foil gauge for use on composite materials, with self-temperature compensation | 2 to 5 | -20 to +200 |

| GF | Foil gauge for use on plastics with low elastic modulus | 3 to 6 | -20 to +80 |

| LF | Foil gauge for use on wood/gypsum | 10 | -20 to +80 |

| PFLW/PLW | Foil/wire series with metal lining for long term use on wood/gypsum | 30 to 60 | -20 to +80 |

| MF | Foil gauges designed for use in high magnetic fields | 2 to 60 | -20 to +200 |

| YEF | Foil gauge for large strain, post-yield measurement up to 15% strain | 2 to 5 | -20 to +80 |

| YF | Foil gauge for large strain, post-yield measurement up to 20% strain | 2 to 20 | -20 to +80 |

| YHF | Foil gauge for very large strain, post-yield measurement up to 40% strain | 2 to 5 | -30 to +80 |

| DSF | Foil gauge for high stress fatigue testing, over 10million cycle fatigue life | 2 to 5 | -60 to +200 |

| DD | “Single side” foil strain gauge for separating bending and tensile strains where only one side of the test specimen is accessible | 3 | -10 to +70 |

| FAC | Crack propagation gauge, for measuring the speed of crack growth | 5 to 20 | -30 to +80 |

| SF | Stress gauges for direct axial stress measurement in plane stress fields | 4 | -20 to +200 |

| BTM | Very narrow gauge for embedding in bolts to measure bolt tensile strain. | 1 to 6 | -10 to +80 |

| BTMC | New design of bolt embedment gauge that can be fixed in minutes using CN adhesive | 0.5 to 3 | -10 to +80 |

| TF | Temperature gauge to measure surface temperature | 2 to 8 | -20 to 200 |

| CBF | Frictional Strain Gauge, when used with special holder does not require bonding, for quick check measurements of strain | 3 to 6 | 0 to +60 |

We also supply gauges in many other configurations, as well as gauges with specific creep characteristics and full bridge gauges for use in transducers. Please ask for further details.

Grid Pattern

The choice of gauge grid pattern is dependent on the type of test to be performed and the strain data required. For simple tension or compression where the direction of strain is known, a single element gauge may be used. If the direction of principal strain is not known then a 3 element rosette can be used to determine the strain direction. Special patterns are also available for torque, stress concentration and residual stress measurement. For advice on the correct pattern for your measurement please contact us.

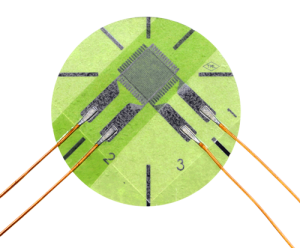

| Code | Description | Image |

| L/LA/LG | Single Element Linear | |

| LK | Single Element – Narrow | |

| LX/BX/BY | Single Element | |

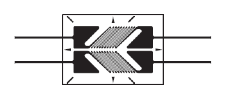

| C/CA/LC/CS/CB | Two Element Cross (0°/90°) |  |

| R/LR/RA/RAS/RS | Three Element Rosette (0°/45°/90°) |  |

| LT | Single Element, Shear (45°) | |

| CT | Two Element, Torque (45°/45°) |  |

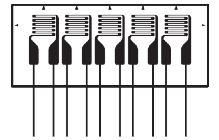

| XV/YV/BXV/BYV | Five Element, Stress Concentration |  |

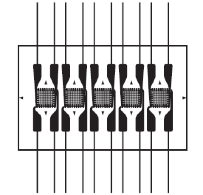

| CV | Ten Element (5 Cross), Stress Concentration |  |

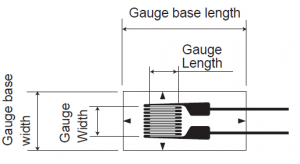

Active Grid Length

The “active grid length”, “gauge length” or “gauge size” all refer to the length of the gauge grid elements that generate a resistance change when the gauge is placed under strain. The total resistance change, and therefore the strain measurement, will be an average over the length of the grid.

The grid length should be selected depending on the measurement type – e.g. short grid for very local strain measurement or long grid for averaged strain measurement over a larger area. Where relevant, discontinuities in the specimen material, e.g. composite material weave or concrete aggregate size, should be accounted for and the grid length selected to average the strain measurement over the required number of such discontinuities (usually a minimum of 2 or 3).

The selection of grid width depends on the geometry and size of your specimen – narrow width grid patterns (LK) are available for axial strain measurements on slender specimens such as rods or pipes.

The gauge “base” or “backing” is the area of material that will be bonded to your specimen. If you have limited space available on your specimen for gauge installation this may dictate backing size. The backing should never be cut or trimmed as there is a risk of damage to the grid which may affect the gauge factor.

Special Functions

Special functions can be selected for some gauge types, defined in the table below. Please ask for details of which gauge types these functions are applicable.

| CODE | Description |

| A | 45° Left Pattern |

| B | 45° Right Pattern |

| T | Integrated Thermocouple |

Gauge Resistance

The majority of TML strain gauges are available in the ‘standard’ resistance of 120Ω. This standard resistance is not included in the part code for brevity.

Other resistances are available, including 350Ω and 1000Ω. A higher gauge resistance reduces the current draw of the strain gauge, which reduces both the power consumption (important if battery powered / wireless signal conditioning is to be used) and the joule heating effect (important on specimens with a high thermal expansion coefficient, such as plastics).

Thermal Compensation

The majority of TML strain gauges are compensated to reduce the effect of apparent strain caused by thermal expansion of the test specimen. The compensation, in ppm/°C should be selected to match as close as possible the linear thermal expansion coefficient of the specimen material. TML gauge backings are colour coded to simplify identification of temperature compensation. Not all gauges are self-temperature compensated; where the number is missing from the part code this indicates that the gauge is not self-temperature compensated.

| Gauge Temperature Compensation | Use for | Common Materials | |

| Name | Linear Thermal Expansion Coefficient (ppm/°C) | ||

| 3 | Composite | Ceramic (Si3N4) | 2.6 ~ 3.3 |

| Carbon / CFRP | 3 ~ 5 | ||

| 5 | Composite | Ceramic (SiC) | 4.6 |

| 8 | Composite / Titanium | Glass / GFRP | 7.9 |

| Ti-6Al-4V | 8.8 | ||

| Titanium | 8.9 | ||

| 11 | Mild Steel / Concrete | Concrete | 7 ~ 13 |

| Cast Iron | 10.5 | ||

| SUS 631 (17-7PH) | 10.6 | ||

| SUS 630 (17-4PH) | 10.8 | ||

| Hard Steel (0.4-0.5C) | 11.2 | ||

| Hastelloy-276 | 11.2 | ||

| Mild Steel (0.1-0.2C) | 11.8 | ||

| Inconel 750 | 12.1 | ||

| Inconel 600 | 13.3 | ||

| Monel | 13.5 | ||

| 17 | Stainless Steel / Copper Alloy | Constantan | 14.9 |

| SUS 310 | 15.8 | ||

| SUS 316 | 16.0 | ||

| SUS 304 | 16.2 | ||

| Beryllium copper | 16.6 | ||

| Copper | 16.7 | ||

| SUS 321 | 16.7 | ||

| Brass | 16.7 | ||

| Bronze | 17.0 | ||

| 23 | Aluminium | Polyimide | 20 ~ 30 |

| Al 2024-T4 | 23.0 | ||

| Aluminium | 23.4 | ||

| Gypsum | 25.0 | ||

| Lead / Lead alloys | 29.0 | ||

| 28 | Magnesium | Magnesium alloy | 27.0 |

| 50 | Plastics | Epoxy (cast) | 45 ~ 65 |

| 70 | Plastics | Polystyrene (PS) | 60 ~ 80 |

| Polycarbonate (PC) | 66 ~70 | ||

| Acrylics | 70 | ||

| ABS | 74 | ||

| Polyacetal (POM) | 80 | ||

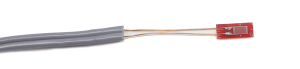

Integral lead wires

The majority of TML gauges are supplied as standard with short 2cm wires attached to the gauge, these are designed to be connected to extension leadwires via a solder terminal connector.

All TML gauges can be supplied with pre-attached extension leadwires. This can save considerable time during gauge installation and simplifies the application of moisture/waterproof coatings. Integral leadwires are denoted in the part code by a suffix comprising a number (which is the length of the leadwires required, in metres) followed by a series of letters (which denotes the type of leadwire). We hold UK stock of a selection of the most popular gauge types with a choice of integral leadwires, please ask for availability. We also offer a small selection available to purchase online at our online store

Selection of extension leadwire depends upon a number of factors including temperature (various high temperature sheath materials are available and 3-wire should be used if there will be a thermal gradient across the leadwire), physical environment (sheaths with improved mechanical or chemical resistant properties) and electromagnetic environment (use shielded cables where electromagnetic interference is a concern). The table below describes the various integral lead wires available. A full chart of lead wire compatibility with different gauge types is available to download here

| CODE | Description | Temperature Range (°C) |

| LJB | 2-wire parallel, vinyl sheath, general purpose (0.08mm²) | -20 to +80 |

| LJBT | 3-wire parallel, vinyl sheath, general purpose (0.08mm²) | -20 to +80 |

| LJC | 2-wire parallel, vinyl sheath, general purpose (0.11mm²) | -20 to +80 |

| LJCT | 3-wire parallel, vinyl sheath, general purpose (0.11mm²) | -20 to +80 |

| LE | 2-wire polyimide coated (max. 1m), very thin & lightweight | -269 to +300 |

| LTSA | 3-core shielded, vinyl sheath, for use where EMI is a concern | -20 to +80 |

| LRT | 3-wire twisted, cross-linked vinyl sheath, improved environmental protection, e.g. for underwater use | -20 to +100 |

| LJQTA | 3-wire twisted, cross-linked polyethylene sheath, e.g. for use in steam | -60 to +125 |

| LXT | 3-wire parallel, special vinyl sheath, chemical resistant | -20 to +150 |

| 6FA-LT | 3-wire twisted, fluorinated resin (FEP) sheath, cryogenic or high temperature | -269 to +200 |

| 4FA-LT | 3-wire twisted, fluorinated resin (PTFE) sheath, for very high temperature | -269 to +260 (+300 short term) |

D5 Creation

D5 Creation